Hand Trucks: Everything You Need to Know

Hand trucks are a type of material handling equipment used in many industries to safely and efficiently move large, heavy objects and materials. They are necessary for the continued functioning of these industries, which include HVAC and construction.

Hand trucks come in a myriad of sizes, materials, capacities, and structures, depending on what objects they’re designed to move. They tend to have two wheels and a vertical frame, and feature a nose plate that slides under an object for easier lifting. They can be electrically powered or motorized, and may come with stair-climbing capabilities.

The hand truck is a versatile tool, but what are all the specific use cases for hand trucks? How do you know whether a job needs a hand truck? And if it does, how do you choose the right one? How do different industries use hand trucks? This guide will serve as a comprehensive overview of all types of hand trucks, and how and why each type is used.

Table of Contents

1

Basic anatomy of a hand truck

2

All the types of hand trucks, explained

3

Hand truck design by object

4

What’s the difference between a hand truck and a dolly?

5

Why are hand trucks used?

6

What industries benefit from hand trucks?

7

How do you decide which hand truck you need?

8

Thinking about a stair climbing hand truck?

Basic anatomy of a hand truck

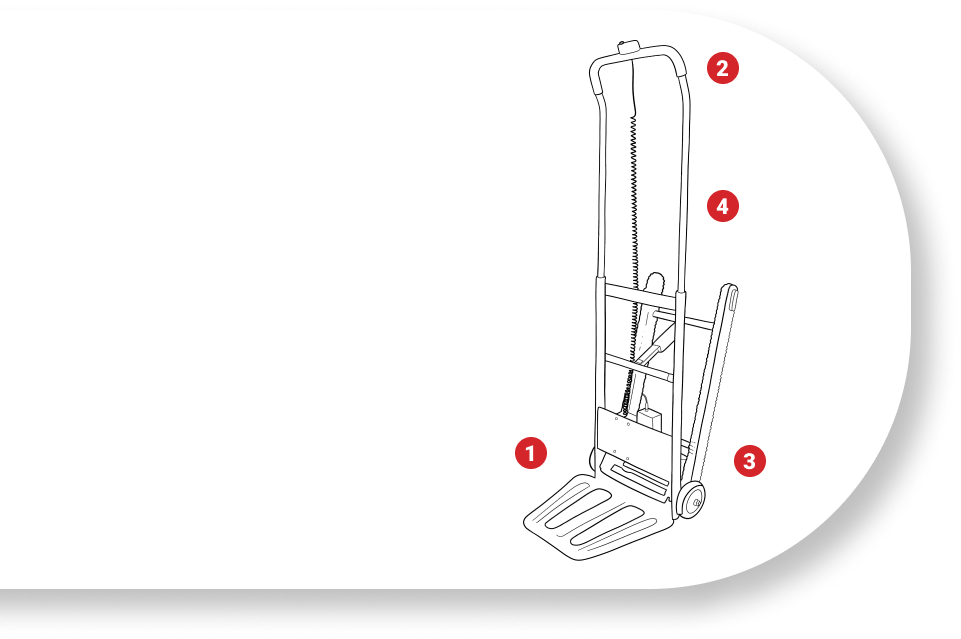

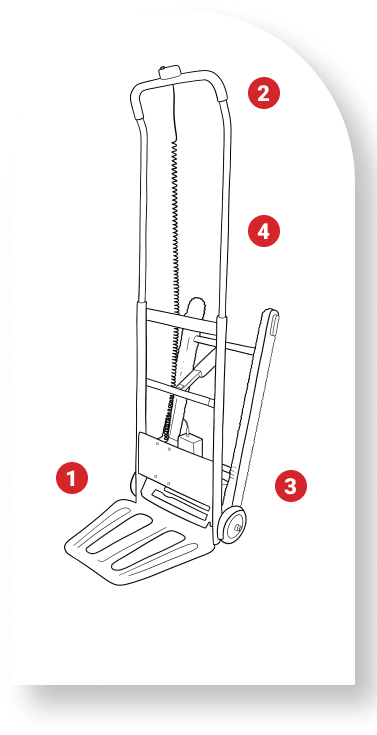

Though hand trucks differ in structure depending on their intended purpose, all variations feature the following parts:

- Nose - the small ledge at the base of the hand truck

where objects are set down for transport. The nose

can also be slid underneath the object that is being

lifted, so the user doesn’t need to manually lift and

place the object. - Handles - used to push the hand truck

forward. - Wheels or tracks

- Frame - the main structure of the truck that holds

everything together and supports the objects being

carried. Hand truck frames tend to be made of either

steel or aluminum. While aluminum is lighter, making

it easier to transport the hand truck itself, steel

sturdier and can handle heavier loads.

All the types of hand trucks, explained

All the types of hand trucks, explained

Hand trucks have varying attributes based on what they’re used for. They can have a combination of features, as well.

Powered hand trucks

Some hand trucks offer motorized features which allow operators to maneuver heavy loads with ease, or even transport loads up stairs. These types of hand trucks are known as powered hand trucks, or motorized hand trucks. They are battery operated, so users don’t need to be near an electrical outlet to get the job done.

Motorized hand trucks, as the term would suggest, use a motor to help rotate the wheels, or otherwise propel the hand truck from point A to point B. They may also offer an automatic lifting function, in which a motor lifts the nose of the hand truck upwards after an object is placed on it, meaning individuals don’t need to manually lift heavy objects.

Stair climbing powered hand trucks are more particular in their design. One style, known as the Push Arm type, has an arm fitted to the bottom of the truck. During operation, the arm, which is situated behind the load-carrying plate, repeatedly folds outwards and downwards, pushing on the top of the stair above and moving the hand truck upwards. The push arm style tends to have a set of two wheels and appears similar to manual, non-motorized hand trucks. They also often include a forward-braking safety feature that prevents the hand truck from rolling off the edge of the stairs during ascension, and keeps the truck from uncontrollably rolling down the stairs during descension.

Some stair climbing models have tracks instead of wheels as their main mechanism of movement, and in these cases they also have a small set of rotating wheels which propel the tracks to spin like a conveyor belt. Stair climbing powered hand trucks can ascend and descend stairs.

Stair climbing mechanisms reduce the amount of effort required by the hand truck user, therefore reducing risk of injury.

Motorized hand trucks may also be foldable for easy storage.

Traditional, non-motorized hand trucks

When you think of a hand truck, the first image that will pop into your head will likely be a truck that is non-motorized, L-shaped and vertical. This is a traditional hand truck. Quintessential and classic, this type of hand truck is normally two wheeled and manually operated, with handles the user can use to push the truck forward.

Non-motorized traditional hand trucks are normally meant to transport lighter loads like boxes.

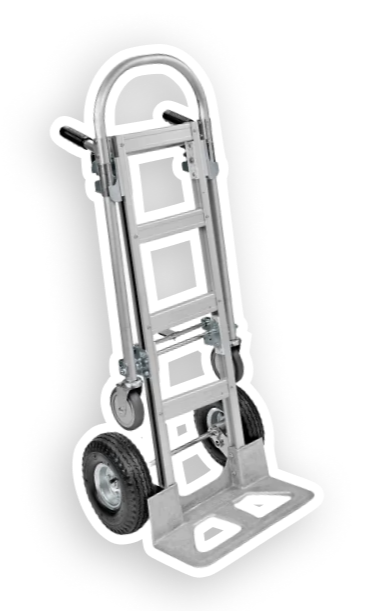

Convertible hand trucks

When in the vertical position, convertible trucks have a standard metal frame, which is used to support the sides of objects when the truck is in motion. The truck is operated by tilting backwards towards the user, and is pushed forward while being held at an angle.

The difference between convertible hand trucks and standard two-wheel hand trucks is that convertible hand trucks can be operated as two- or four-wheelers. This type of hand truck has two main wheels, and another set of smaller wheels that come into use when the frame is folded out.

Convertible trucks can be unfolded to reveal a larger platform supported by four wheels. This form is used to support larger loads.

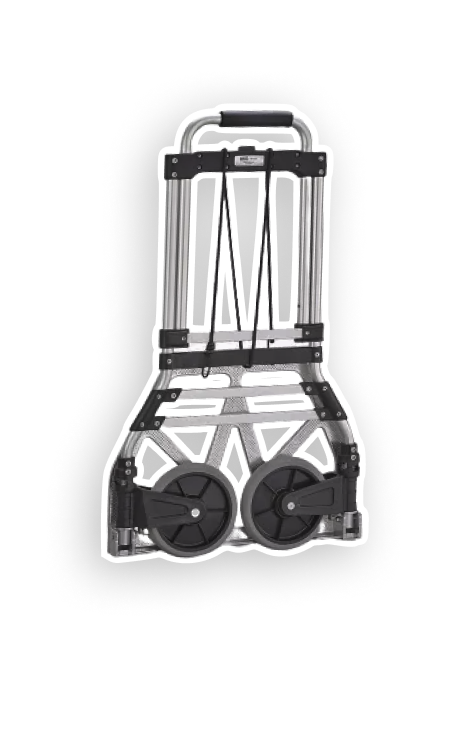

Folding hand trucks

Hand trucks may sometimes be collapsible for convenient storage in closets when not in use, or for easy transport in vehicles. Folding hand trucks usually have a vertical frame, but many types of hand truck can be foldable.

Hand truck design by object

Whether you’re looking to load boxes into a moving truck or transport a large piece of equipment, a hand truck is a worthy investment. Based on the task they are made to perform, all hand trucks have some combination of features that are made to work best.

General purpose

General purpose hand trucks feature two wheels and a vertical frame. They are designed to lift boxes, crates, bins, and raw materials. They may be foldable, and can be - but often are not - motorized.

Appliance

Appliance hand trucks are made to handle heavier loads than other types. They can lift heavy, bulky objects such as refrigerators, ovens, and vending machines. They can be two or four wheeled, or both. They tend to start off two-wheeled, but come with a lever built in which, when released, lets another set of wheels pop out behind the frame. These wheels sit at a 90 degree angle from the frame, and provide additional support for the hand truck operator by acting as a cantilever. This type of hand truck may also include stair climbers.

Objects are often secured to the frame with belts to prevent them from falling forward during operation.

Contractors, construction workers, and moving companies tend to use this type of hand truck most often.

Furniture

Furniture hand trucks are designed to handle large objects like tables, file cabinets, and dressers. Their weight capacity ranges from 300 - 1,000 pounds. They often have multiple configurations; they can operate on two wheels, or convert to a four-wheeled platform for bulkier objects.

Moving companies in particular tend to benefit from this type of hand truck.

Pail or drum hand trucks

These hand trucks are used to move large, cylindrical containers such as buckets, pails, drums, or barrels. They’re usually two-wheeled, and come with additional supports like bungee cords to secure their loads.

These hand trucks are often used in industries where bulk amounts of materials must be moved at once. These include food processing, pharmaceutical manufacturing, and plastics manufacturing.

Beverage

This type of hand truck has a lightweight aluminum frame supported by two wheels. It’s used to transport bulky and sometimes awkwardly-shaped objects like beverage cases and 5-gallon water bottle tanks.

Beverage hand trucks often have lightweight frames with two wheels. They’re used by beverage delivery workers that travel from place to place, so they may also have stair climbing mechanisms to make it easier to maneuver up stairs or curbs during deliveries.

Cylinder hand trucks

This type of hand truck is specifically designed to carry and store cylindrical gas cylinders like propane tanks. They have a vertical frame, and can be two or four wheeled. Some types have a nose plate, while others have a strong magnet built into the frame that holds gas tanks in place.

Multiple industries benefit from these hand trucks; they’re used for a multitude of manufacturing, construction, and medical applications.

What’s the difference between a hand truck and a dolly?

The terms “hand truck” and “dolly” are used interchangeably, but they’re not quite the same thing. Technically, hand trucks are L-shaped and vertical. They feature two large wheels at the base of the frame. Convertible hand trucks are not considered dollies, because even though they can resemble a four-wheeled platform, they still have a nose plate (making them L-shaped) and are able to stand vertically.

Dollies, on the other hand, are always four-wheeled and horizontal. They’re a raised, flat platform that may or may not have a handle attached. And unlike hand trucks, they don’t have a nose plate, so items need to be lifted onto their platforms.

Dollies and hand trucks have similar applications. Dollies offer more stability than hand trucks since their platforms are always flat, but hand trucks are best for moving objects across non-flat surfaces, such as up and down stairs.

Variations of hand trucks have been found in recorded history since the 1700s, when the “sack truck” was invented. During this period of time, importing spices by ship was becoming a common practice, and that meant that large, heavy sacks of spices needed to be transported from the docks to their destination.

This era had children as young as 10 years old employed in physical labor jobs, including unloading ships (needless to say, the laws were different back then). The sack truck was used by children to transport the heavy sacks of spices that they otherwise wouldn’t have been able to lift.

Despite this unscrupulous origin, hand trucks are so useful because they make it easier and safer to transport heavy materials. They reduce the strain on muscles and joints that comes from lifting hefty objects, and turn two-person jobs into one-person efforts.

Safety considerations

The use of hand trucks in workplace environments is a great way to reduce the risk of lifting-related injuries, such as strains, sprains, and in serious cases slipped discs and broken bones. And fewer workplace accidents means happier employees, better employee retention, and less workers’ compensation claims.

According to the National Institute for Occupational Safety and Health (NIOSH), a leading cause of work-related injuries that necessitate treatment in an emergency department is overexertion, which can occur when a person attempts to lift an object that is heavier than they can physically handle, or from repeated movements that cause stress on the body. Hand trucks specifically alleviate that issue by taking on a majority of an object’s weight.

Efficiency in the workplace

Since hand trucks allow people to lift objects that otherwise would be physically impossible to handle on their own (you try lifting a refrigerator with your bare hands!), they also reduce the need for multi-person lifting. An object that would otherwise require two or even three people to hoist up, can now be taken care of by a single person.

In addition, hand trucks make for faster transport. Simply pushing an object along on wheels is much easier than walking while holding it.

What industries benefit from hand trucks?

Hand trucks are utilized by workers panning a wide range of industries and occupations.

Medical

Hand trucks are an important part of a hospital’s daily functioning. Medical equipment and oxygen tanks have to be moved from place to place on a regular basis.

Due to this need, drum hand trucks are especially useful in medical settings. General purpose hand trucks are also often needed, since boxes of supplies have to be moved in and out of storage.

Construction

Similar to manufacturing, construction workers have a frequent need to move large quantities of heavy materials. And contractors that are renovating or building homes need a way to carry appliances into the homes.

Of course, forklifts and other larger equipment can be used in construction scenarios, but when it comes to moving objects into buildings, hand trucks are the way to go.

Moving Companies

Movers need to employ multiple types of hand trucks, depending on the size of the move and the objects they’re going to be moving. They could be tasked with handling anything from a few boxes to several large appliances.

For large moves, movers tend to use convertible, foldable hand trucks that have a wide range of uses and a high weight capacity, yet are portable. Stair-climbing features may also be necessary, to avoid injury while transporting bulky objects out of multi-story homes.

For relatively smaller moves, or even for people who are moving house without the help of movers, traditional general purpose hand trucks will do the trick.

HVAC

As you might imagine, the HVAC industry has a frequent need to transport large, heavy heating and cooling units. HVAC workers tend to use convertible four-wheeled hand trucks with steel frames and oversized noses to keep loads stable. HVAC hand trucks are often equipped with pneumatic tires as well, for easier maneuvering.

Hand trucks are most commonly used in HVAC applications in their four-wheeled form. To pick up a heavy piece of equipment, the nose of the hand truck is slid underneath it, then a belt is used to secure the equipment to the frame. The truck is then tilted back on the 2nd set of wheels, and the frame is used as a base while the truck is pushed.

This video demonstrates how it’s done: Valley Craft HVAC Hand Trucks

How do you decide which hand truck to use for the job?

With all the types of hand trucks available, you have to be sure that you’re choosing the right one for the task you need to perform. Though hand trucks make jobs safer when used correctly, improper use, such as attempting to load a 200lb object onto a hand truck with a 100lb weight capacity, can lead to injury.

When picking out hand carts, here are the things you need to keep in mind:

- Weight capacity. Ensure that the truck you pick can handle the materials you’re transporting.

- Nose size. Does lifting the object entail sliding the nose underneath?

- Standard vs stair climbing. Are you going to need to ascend or descend stairs?

- The weight of the truck itself. Will the person operating the hand truck physically be able to lift up the truck itself? Is lifting the truck a necessary aspect of the job? Hand trucks with steel frames can be surprisingly heavy, so keep that in mind.

- Portability. Where are you going to store the truck afterwards? Are you going to need to load it into a vehicle at any point?

- Frame height. How tall is the object you’re transporting? Are you going to be stacking multiple objects (such as boxes) on top of one another